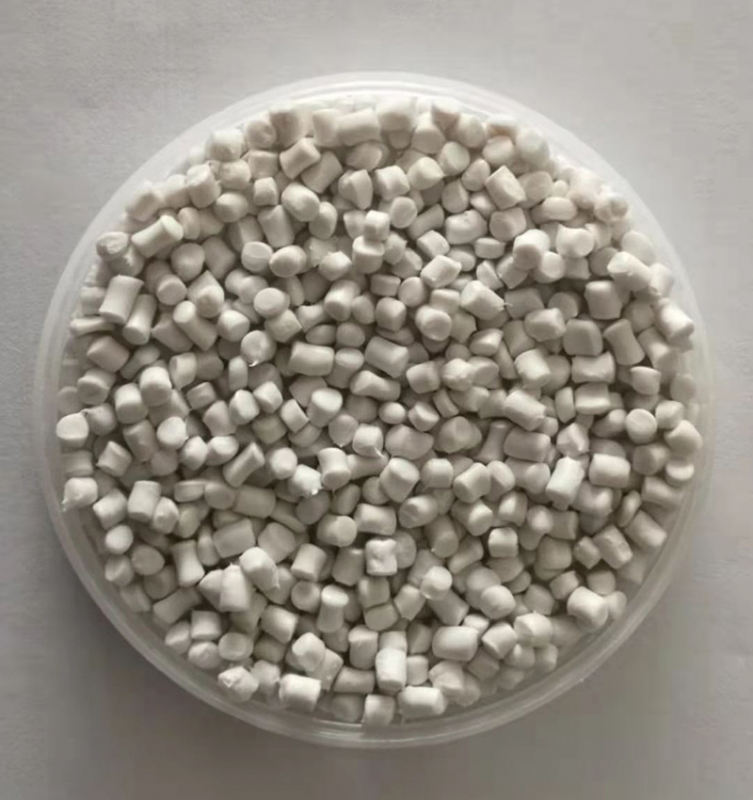

Poor insulation of PVC cable material

Due to limitations in PVC material research and the influence of plasticizers and other additives, the insulation properties of PVC cable materials have a certain time limit. For ordinary cable materials in our company, if there is a significant deviation in insulation, there are several main reasons for the following problem analysis based on data:

1. Excessive impurities

The mixing of impurities can have adverse effects on cable materials, and excessive impurities can cause insulation problems. These impurities may mainly come from PVC resin and various additives, or they may come from the mixing and feeding process themselves.

2. The powder particles are too coarse

Powder additives are generally used after grinding in cable materials. If there are any patterns or mechanical failures that cause the added powder particles to be too coarse, it will have a negative impact on the insulation of the cable material.

3. Heavy metal issues with coloring agents

The "497" pigment is a heavy metal salt. These studies on heavy metal ion technology can effectively improve the conductivity of network cable materials and reduce their insulation. Therefore, the selection of cable pigments is very important.

Moisture issue with cable materials

Due to the presence of fillers with a certain proportion of working time in cable materials, some students may also have a certain degree of influence on the proportion of low-grade plasticizers (or plasticizer substitutes) in their studies. Cable materials that are not easily affected by moisture during the development process may also face economic and social environmental problems from enterprises in certain seasons.

The moisture absorption of cable materials and the teaching process of packaging design and packaging materials have a significant impact on social relations. It should be possible to strengthen drying, cool them to a certain economic environment temperature, and then seal them tightly. In addition, we should continuously improve the packaging materials of Chinese enterprises and increase moisture-proof measures.

At the same time, attention should also be paid to potential degradation and surface induced pseudo wetting phenomena.